To What Pressure Should I Fill My Mobile A/C?

For a mobile air-conditioning system to run efficiently, the correct amount of refrigerant must be installed in the system. Both an under– or over-charge will affect efficiency, and the latter could even damage the system. But how does one hit the proverbial “sweet spot” when charging?

START BY KNOWING SYSTEM CAPACITY

The type of refrigerant as well as the total system capacity is usually marked on a sticker in the engine compartment . However, most systems do have residual refrigerant left in them. Therefore, unless you empty the system before filling, your should not assume you need to add that full amount. Instead, low– and high-side pressures should be used to help you reach the appropriate refrigerant level for your system.

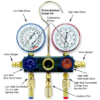

USE A GAUGE TO MEASURE PRESSURES

Knowing the high– and low-side pressures can tell you almost everything you need to know about how your system is functioning.

Many A/C refill cans come complete with a pressure gauge which will communicate a bit of what’s going on within your system and will also help you approximate how much refrigerant to dispense. FJC’s Part #s 501 and 525 are great examples of this. These gauges are accurate and offer an easy and inexpensive way to measure the low side pressure in your system.

On the other hand, the low side pressure is just half of the information you should consider for a precise charge. An A/C system is effectively split into two halves: the low– and high-pressure sides, and knowing the pressure on both helps to give you the most complete picture of what’s going on in your system.

The best way to measure the high-pressure side of your system is with a manifold gauge set. FJC sells many different types, depending upon the refrigerant in the system, whether you prefer manual or quick couplers, alumium or brass. You can see them here.

Once you have your manifold set, it’s important to know that pressures can vary based on ambient temperatures (the warmer it is outside, the higher the pressure will be) as well as the system itself.

PROCEDURE

First check the pressure with the system at rest (compressor off for at least 30-mins to allow the high and low pressures to equalize). Attach the hoses and gauge set to the high and low side ports of your AC system.

- With the engine off, read the low and high-pressure gauges. They should be the same. (It takes a while to equalize, that’s why you must wait 30-mins to check static pressure.)

- Measure ambient air temperature at the vehicle and under the hoodWITH A THERMOMETER (do not use weather service temperatures). The static pressure correlates to the temperature of the AC components under the hood, not outside in front of the vehicle.

- Compare the pressure readings to a pressure-temperature chart. We have one here.

IF LOW AND HIGH SIDE PRESSURES ARE BOTH LOW, THE ISSUE MAY BE:

- Refrigerant filled below manufacturer specification

- Compressor under-performing or not engaging

IF LOW AND HIGH SIDE PRESSURES ARE BOTH HIGH, THE ISSUE MAY BE:

- System may filled above manufacturer specs

- Internal contaminants obstructing the condenser

- Broken condenser fan

- Failed or Failing compressor

IF LOW SIDE PRESSURE IS LOW AND THE HIGH SIDE IS HIGH, THE ISSUE MAY BE:

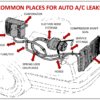

- Leak or restriction in the system

IF LOW SIDE AND HIGH SIDE PRESSURES ARE EQUAL OR NEARLY EQUAL, THE ISSUE MAY BE:

- Failed or Failing compressor

- Failed or Failing expansion valve

LMK 2021