How Different is an R-1234yf Mobile Air Conditioning System?

All automotive air conditioning systems are self-contained structures which cool the cabin of a vehicle by changing the phase of refrigerant from gas to liquid and back again by applying and releasing pressure on it. The ability of refrigerant gas to change its physical properties as it is compressed and cooled is what makes the air conditioning system produce cool air. If you are already familiar with R-134a systems, you will find the newer R-1234yf systems are very similar. In general, the differences can be summed up with the following:

- The pressure/temperature relationship of R-1234yf and R-134a are very similar, so there’s nothing earthshattering with respect to the refrigeration cycle between the two refrigerants.

- Systems using R-1234yf refrigerant must also use an evaporator compliant with SAE J2842.

- The recovery/recycling procedure for R-1234yf refrigerant is a little more complicated than R-134a due to equipment that has more sophisticated leak and purity check capabilities.

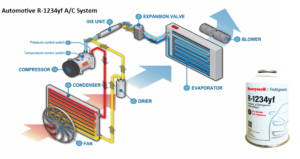

Each part of both system is connected by tubing or hoses which form a closed loop through which the refrigerant flows. Since this is a continuous circle, there’s no specific start or end point; everything occurs simultaneously. However, we will start with the compressor; often considered to be the “heart” of the system.

Compressor (IN: Low Pressure Gas OUT: High Pressure Gas)

Like a heart, the compressor is a pump which pushes the refrigerant through the refrigerant line. As it pumps the refrigerant it also compresses it from a low pressure gas to a high pressure gas. This high pressure also heats the refrigerant. Because of its high pressure contents, this called the “high side” of the system.

Condenser (IN: High Pressure Gas OUT: High Pressure Liquid)

The hot, high-pressure refrigerant flows through the high-pressure tube towards the condenser. The condenser is a series of coils, similar to a radiator, which sits in front of the car’s actual radiator. As air passes over the condenser it removes heat from the refrigerant. The refrigerant condenses into a liquid as it cools (which is why it’s called a “condenser”).

Accumulator or Receiver/Drier (IN: High Pressure Liquid OUT: High Pressure Liquid)

Next, the refrigerant enters into either a receiver drier or an accumulator. Although different, both devices function to filter the refrigerant and absorb any moisture from the system. The receiver/drier separates liquid refrigerant from any residual vapor refrigerant. The high-pressure liquid refrigerant sinks to the bottom and is sent to the expansion valve.

Internal Heat Exchanger (IHX)

The IHX, also sometimes called a suction line heat exchanger, has no moving parts, but helps the system operate more efficiently. The liquid refrigerant from the high side flows throught the outer shell of the IHX and is subcooled prior to entering the H-Block. The vaporized refrigerant from the low side flows through the inner portion of the IHX, absobs heat from the high side refrigerant, and is superheated before heading to the compressor. This process increases performance level to the R-134a systems.

H-Block Thermal Expansion Valve (TXV) (IN: High Pressure Liquid OUT: Low Pressure Liquid)

The now-liquid refrigerant flows through a small valve. (In R-134a systems, this was typically an orifice tube).The valve restricts the flow of refrigerant allowing only a small amount through at a time, and also relieves the pressure. When the pressure is suddenly reduced, the refrigerant becomes very cold. This is the point where the High Side becomes the Low Side.

Evaporator (IN: Low Pressure Liquid OUT: Low Pressure Gas)

The cold, low-pressure refrigerant then goes into the evaporator: the only part of the air conditioning system that is actually in the passenger compartment. Since the refrigerant is cold now, an electric blower fan pushes the cold air through the vents and into the passenger cabin. Since refrigerant has a very low boiling point, the hot air causes it to quickly evaporate back into a gas (which is why this part’s called the “evaporator”). As it evaporates, it absorbs heat from the air passing through.

LMK 2021