What is a Spark Free/Spark Proof Tool?

In general, “Spark Free” tools are made of materials that do not contain iron and which utilize manufacturing processes which reduce the risk of a spark being created while the tool is in use . They protect against both fire and explosion in environments that may contain flammable liquids, vapors, dusts or residues. (cityoflightpublishing.com) When working in confined spaces and areas where flammable gases or dusts are present, using a non-sparking tool is the best practice.

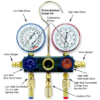

You may have noticed the “Spark Proof” designation (below) on FJC’s R-1234yf tools and wondered what that means. Since R-1234yf has been designated by ASHRAE as a 2L flammable gas (mildly flammable) the tools associated with its use must be spark free, or “ignition-proof”.

![]()

In general, ignition proof tooling provides a safe, spark –free work environment. This means the tools produce no heat or sparks and are ideal for working with mildly flammable materials, like R-1234yf.

The Occupational Safety and Health Administration’s (OSHA’s) Hand and Portable Powered Tools and Equipment standard states “Each employer shall be responsible for the safe condition of tools and equipment used by employees, including tools and equipment which may be furnished by employees.” Therefore, providing and maintaining non-sparking tools in a safe environment is vitally important when working with R-1234yf.

Here are some common-sense tips for proper use and maintenance of non-sparking tools:

- Keep non-sparking tools clean and free from contaminants which may impair the non-sparking properties.

- Tools are designed for specific uses, and should not be used in a manner inconsistent with their intended purpose.

LMK 2020