Vacuum Pump Maintenance

A vacuum pump is a literal workhorse in aftermarket air conditioning. Once you’ve chosen and purchased the right pump, your goal should be to protect and maintain your investment.

Because it removes moisture, acid and other contaminants from an A/C system, vacuum pump oil can become contaminated fairly quickly. Once the oil is compromised in this way, the pump’s ability to remove moisture from the system is reduced and corrosion may occur. This will cause the overall performance of the vacuum pump to diminish, resulting in poorly evacuated systems. Unfortunately, by the time that happens it is too late.

What can you do proactively to keep your pump working for a long time?

- Before using your pump, read its accompanying instructions. If you need to refer to them at a later date, rest assured that all FJC vacuum pump instructions are posted on our website page for that pump.

- Regularly check electrical cord and plug for wear or damage. If damage or excessive wear is found, have cord replaced by a licensed electrical technician.

- Check oil level through oil sight glass before each use. The main cause of vacuum pump failure is low oil levels and contaminated oil.

- Change the oil on its recommended schedule; after evacuating an A/C system that was contaminated, or which had a compressor burnout; or if it looks dirty, cloudy, or smells bad.

- Warm up the pump with the inlet blocked. By running the pump with the inlet blocked before connecting to your application, fewer vapors will condense in the pump oil.

- Never block a pump outlet. At the very least, blocking the pump outlet will cause the pump to stop. However, the resulting pressure could also loosen the seal around the oil sight-glass, causing it to leak and need repair.

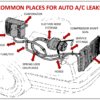

- After pulling a vacuum, close the low side valve and let the vacuum hold for 15 minutes. If it is not able to hold for that long, you likely have a leak and may need to replace/repair components on the pump.

- Run the pump after use with the inlet blocked to purge solvents from the oil. By operating the pump near its highest vacuum level, but with good air flow, many solvents in the oil can be purged, reducing internal corrosion during shutdown.

- Always disconnect vacuum pump from electrical source before performing any maintenance.

- Store vacuum pump in a clean dry place.

By implementing a thorough pump preventative maintenance program, nearly all unexpected vacuum pump failures can be prevented, and when carefully maintained, a vacuum pump will provide years of reliable service . At the end of its useful life, be sure to dispose of all the vacuum pump components according to all state, federal and local regulations.

LMK 2021