Should I Choose a Brass or Aluminum Manifold Gauge Set?

For an A/C tech, a quality set of manifold gauges is an important diagnosis and service tool. We’ve referenced the issue of brass vs aluminum within the text of a previous blog, but since we’re still receiving questions about it, we’ve decided to dedicate an article exclusively to this question: What is the preferred material for manifold gauge sets, brass or aluminum?

Surprisingly, the material from which the set is made has no effect the quality of the set. In many cases it is simply a matter of personal preference. In general, the quality of a gauge set should be evaluated by how well it endures high pressure and corrosion from the refrigerant. Another quality indicator is the precision with which the parts were manufactured as this determines the likelihood of leakage. Check out some FJC brass sets here and some aluminum sets here.

In terms of pricing, although the metal aluminum is less expensive than brass, aluminum manifold sets may still be more expensive than brass, for example, if it has a sight glass to observe the flow of refrigerant, a feature many techs desire.

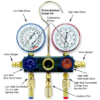

More important than the material they’re made from, buyers should concern themselves with the quality of the set, and the presence of required/desired features. Some of the most important considerations are:

- Refrigerant compatibility

- Large, easy to read color-coded gauges

- Gauge protectors

- Value

- Accuracy

- Manual vs quick coupler

- Endurance and Durability

- User friendliness

- Needed adapters

- Sight glass

- High pressure SAE J2196 hoses with adequate length for your needs

LMK 2020