O-Ring Care: Lubricants and Conditioners

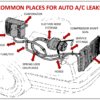

O-rings are small but vital donut-shaped gaskets in an automotive A/C system. They are seated in such a way as to create a leak-free area at each connection where the hard metal and soft O-ring meet. O-ring lubricants and conditioners extend the life of O-rings by creating a surface film which seals the o-ring and metal surface. In addition, they protect O-rings against drying and cracking, which is the most common cause of A/C system leaks. Lubricants and conditioners saturate the O-ring, causing a very minor swelling of the HNBR material. In this way, water and debris will be less likely to enter the system, and refrigerant will be less likely to escape.

There are two primary ways to condition/lubricate O-rings:

FJC O-ring Lubricant Spray

During O-ring installation use FJC O-ring Lubricant Spray (Part 2206) to decrease the surface friction of the O-ring, helping to prevent abrasion, pinching or cutting of the o-ring. Apply a thin, uniform film of lubricant over the entire surface of the O-ring every time you install one to help ease installation and seating of the O-ring. FJC’s convenient spray also helps get the lubricant into tight spaces.

FJC 134a PLUS Additives

Many of FJC’s R-134a products with additives contain O-ring conditioners. For example, during a refrigerant charge, our Extreme Cold™ line, and our “Leak Stop” refrigerants (615DT, 618, 618DT, 623, 623DT, 675, 675DT) will protect seated O-rings from drying and cracking and cause a slight swell of the O-rings, helping to seal leaks in O-rings and all rubber components.

O-rings are used at every connection of an A/C system, creating a sealed, closed system. It is crucial they are the correct size, installed and seated correctly, and properly lubricated/conditioned to work effectively.

LMK 2021