SELF-SEALING VS PUNCTURE STYLE CANS

[vc_row][vc_column][vc_column_text css_animation=”slideInLeft”]Understanding EPA-Mandated Self-Sealing Refrigerant Cans and Dispensing Equipment

The Clean Air Act mandates that the Environmental Protection Agency (EPA) protect air quality and improve the stratospheric ozone layer. By implementing regulations under Section 608 of this act, the EPA regulated or phased out substances which are known to contribute towards global warming or the destruction of the ozone layer. Section 608 therefore introduced several restrictions to the sale of refrigerants. Among these restrictions is the stipulation that small cans (less than two pounds) must be equipped with a “self-sealing” valve to prevent refrigerant from venting into the atmosphere.

For this reason, refrigerant cans manufactured in 2018 and later were redesigned to include a specialized valve which automatically reseals the can when the dispensing tools are removed.

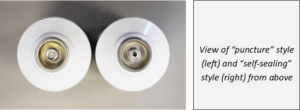

The aerial view of the cans (below) shows the major differences in cap appearance between the traditional “puncture” style cans and the new cans. In the old design, a thin metallic membrane in the center of the threads is permanently pierced by the dispensing tap, opening refrigerant flow from the can.

The self-sealing can on the right replaces the foil with an internal Schrader-like valve which regulates flow dependent on the pressure applied by the dispensing tap. A unique benefit of the “self-sealing” can is that the dispensing tap can be completely removed from the can without venting the remaining refrigerant. When the tap is removed, pressure is released from the internal valve allowing the mechanism to completely seal the top of the can. As a result, each can is preserved for multiple uses: benefiting technicians as well as the environment.

The differences in can tap technology are apparent on the side view. The “puncture” style on the left (below) has a hollow thread body, while the valve mechanism on the “self-sealing” cap to the right rests in the center core of the threading and extends down the dip tubing. The spring-loaded valve travels vertically through the center body of the cap, increasing flow the further it is depressed into the can.

Despite the similarities in exterior styling of the two can taps, the “puncture” style can tap will not work on “self-sealing” cans. The internal mechanisms of the “self-sealing” can tap function entirely differently from the legacy part, and the two dispensers should be used only on the correct can.

One of the important design specifications of the “self-sealing” tap is the dispensing actuator, which is designed to meet specific tolerances of depth and diameter prescribed by the internal can cap valve (as seen in the picture above).

Notable differences also include distinct internal mechanisms for starting and controlling flow as well as integrated back flow prevention to maintain safe operating pressure in the can and dispensing equipment.

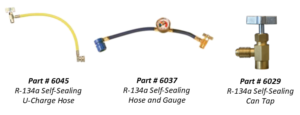

The significant differences in the functionality of caps creates the necessity for specifically-designed dispensing equipment compatible with “self-sealing” cans. FJC’s R-134a dispensing equipment for self-sealing cans can be seen below. We will no longer be selling the puncture-style cans or dispensing equipment.

Let us know if you need any additional information and we will be happy to help.

[/vc_column_text][/vc_column][/vc_row]